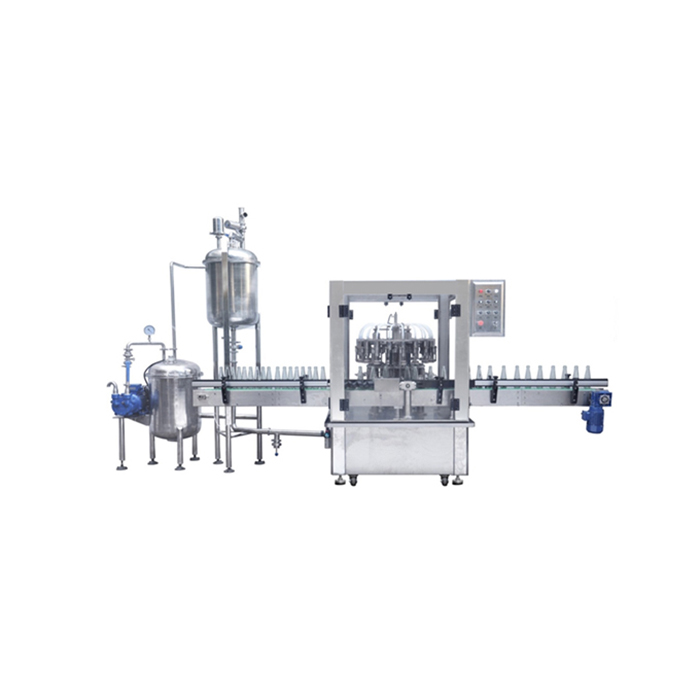

Paradicsom szósz Rotary töltő kupakoló gép

Our factory has been expert at filling packing machines near 10 years with rich expereince, welcome to visit our factory at any time. ( working time. )

This machine is automatic detect bottle (no bottle no filling), filling, automatic fall rubber plug (no bottle, no capping), automatic out of the bottle and some other functions. Compared with other congeneric filling machine, this machine running stable, low noise, high yield, convenient maintenance, safe and stable. It’s most ideal medicine bottle filling machine, Fully meet the requirements of GMP. For special bottle filling materials, our company can design and manufacture. This filling machine is automatic feed bottle, bottle detect, filling, cover rubber plug and outside capping.

Technikai paraméterek

Kitöltési mennyiség: 5-100 ml (testreszabható)

Termelési kapacitás: 30-60 palack / perc

Fedél gumi dugójának hozama: ≥99%

töltési mennyiség pontossága: ≥99%

Teljesítmény: 1 kW

Feszültség 110/220 / 380V

Frekvencia: 50 / 60Hz

Súly: 550 kg

Szállítási határidő

1. Before delivery,machine must be tested and photoed(with or without the packaging),also video

2. After photo and video sent,the balance payment will be asked to pay,our factory will delivery machine on the seconds of full payment arrived to our account.

3. Buyer are warmly welcome to inspect the manufacturing of machine.

Technikai támogatás

1. Sales person online service from 8:00 am to 10:00 pm .

2. Engineer can be arranged for readjusting and installing at the buyer's factoroy,but relative fees should be born by the buyer

Együttműködési márkák

Schneider, Siemens, Mitsubishi, AirTAC, SICK, Omron, Panasonic stb.

Gyors részletek

Típus: Töltőgép

Állapot: Új

Alkalmazás: ital, vegyi, árucikk, élelmiszer, orvosi

Csomagolás típusa: Palackok

Csomagolóanyag: üveg, fém, műanyag

Automatikus fokozat: Automatikus

Hajtott típus: Mechanikus, Elektromos, Pneumatikus

Feszültség: 110/220 / 380V

Teljesítmény: 1 kW

Származási hely: Sanghaj, Kína (szárazföld)

Márkanév: VKPAK

Méretek (L * W * H): 2000 * 1500 * 1700 mm

Súly: 550

Minősítés: CE ISO9001

Vevőszolgálat: A mérnökök rendelkezésre állnak a gépek tengerentúli kiszolgálására

Cikk: Paradicsom szósz Rotary töltő kupakoló gép

Szolgáltatás: Átgondolt

Minőség: garantált

Ár: Versenyképes

Teljesítmény: Kiváló

Karbantartási ráta: alacsony

Felépítés: Rotary

Töltőszelep fej: 1 vagy több

Töltőanyag: Folyékony paszta

Keret: rozsdamentes acél

A Tomato Sauce Rotary Filling Capping Machine is a specialized piece of equipment designed to fill and cap bottles with tomato sauce automatically. This type of machine is commonly used in food processing plants and factories that produce large quantities of tomato sauce.

The filling and capping process is done by a rotating carousel that holds the bottles in place as they move through each station. At the first station, the bottles are filled with tomato sauce using a series of nozzles that control the flow of sauce into the bottle. The machine is designed to fill the bottles accurately, ensuring that each bottle is filled to the correct level.

After the bottles are filled, they move to the capping station where they are sealed with a cap. The machine uses a variety of mechanisms to apply and tighten the caps onto the bottles, including screw capping, snap capping, or twist-off capping.

Tomato sauce rotary filling capping machines come in a variety of sizes and configurations, depending on the production needs of the manufacturer. Some machines can fill and cap hundreds of bottles per minute, while others are designed for smaller batch sizes.

Overall, a tomato sauce rotary filling capping machine is an essential piece of equipment for any food processing plant that produces large quantities of tomato sauce. It is an efficient and reliable way to ensure that each bottle is filled and capped accurately, helping to improve the quality and consistency of the final product.